| View previous topic :: View next topic |

| Author |

Message |

jonc

Joined: 21 Sep 2010

Posts: 584

Location: Cheshire, UK

|

Posted: Mon Oct 19, 2015 2:09 pm Post subject: Posted: Mon Oct 19, 2015 2:09 pm Post subject: |

|

|

The other side of the car is a similar story:

Access allows an assessment of the inside of the sill section - fortunately all looks in good order:

Once completed, it is all painted and waxoyled, and the original rubber tread is cleaned up and refitted:

Here you can also see the new staple covers:

|

|

| Back to top |

|

|

jonc

Joined: 21 Sep 2010

Posts: 584

Location: Cheshire, UK

|

Posted: Mon Oct 19, 2015 3:36 pm Post subject: Posted: Mon Oct 19, 2015 3:36 pm Post subject: |

|

|

David fits the sealed-for-life ball joints which are a later (and superior) one to the original ones on the car. Now that I have the car back and have driven it, I can tell the difference a new, tight set of joints makes. The car is far more precise in its handling and positioning at high speed.

You can see that the wire locking of the brake callipers have also been redone.

You may recall that some time ago I was trying to sort out the starter inhibit. I had sorted out the wiring to the switch on the gearbox, and also replaced the switch itself but it was still not working properly.

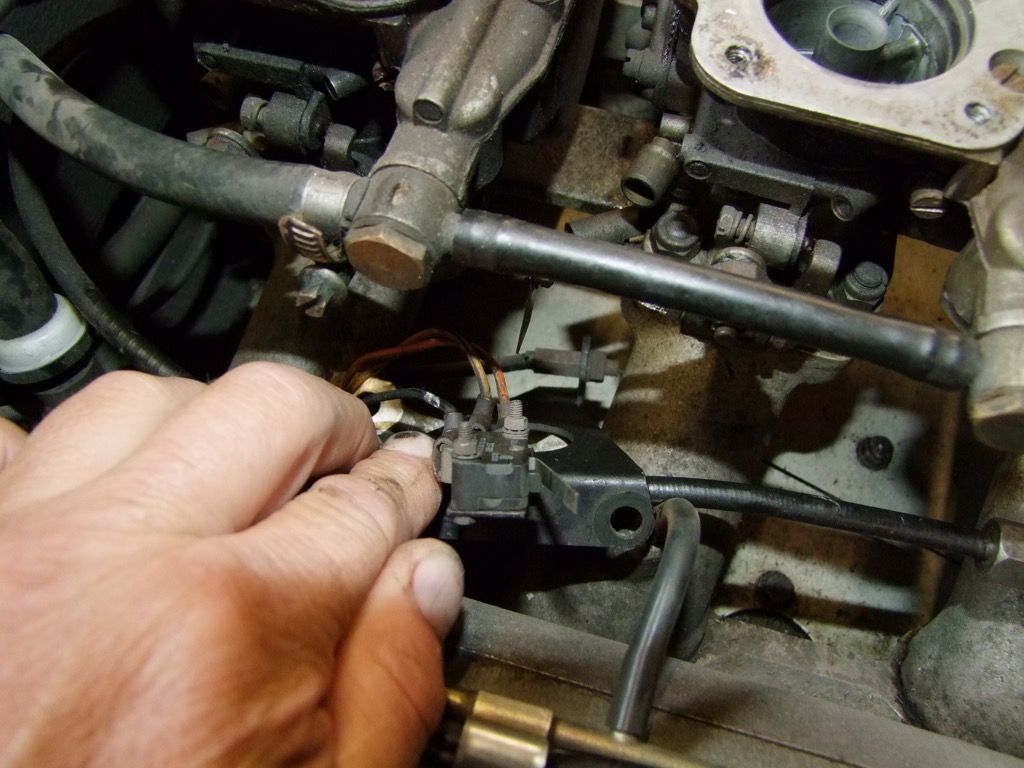

I asked David to look at this. It turned out that my replacement switch was also faulty! David supplied a good quality one which has sorted out the problem.

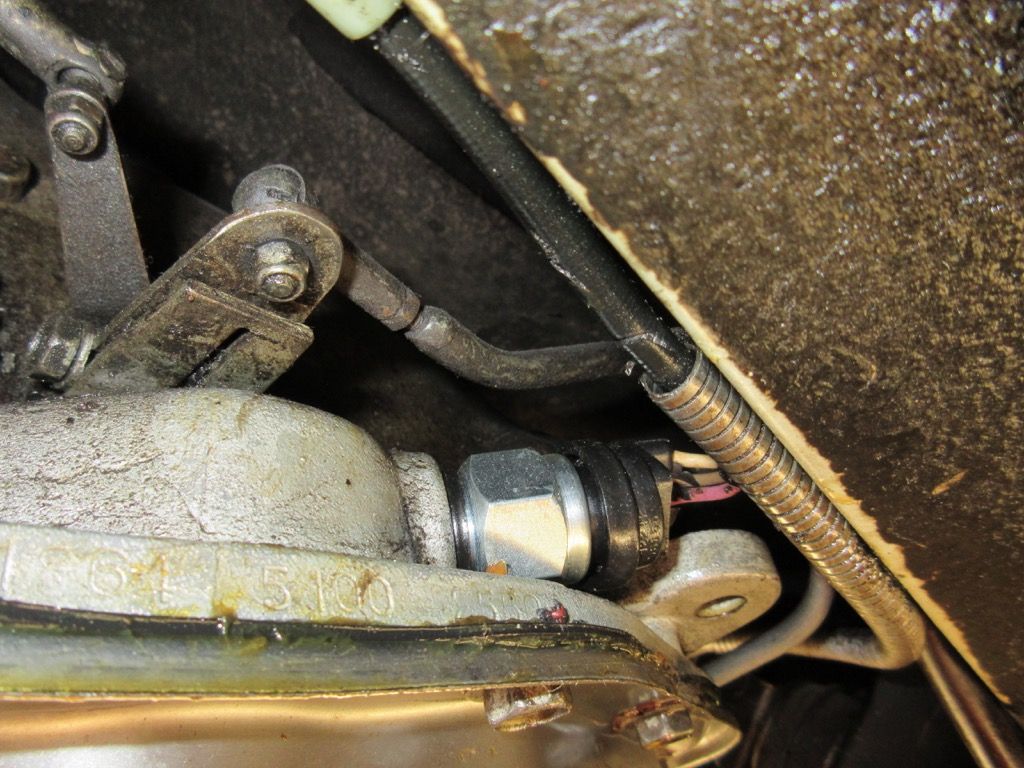

He also replaced the sump pan with a new one which has a built-in drain plug since my after-market drain plug was leaking:

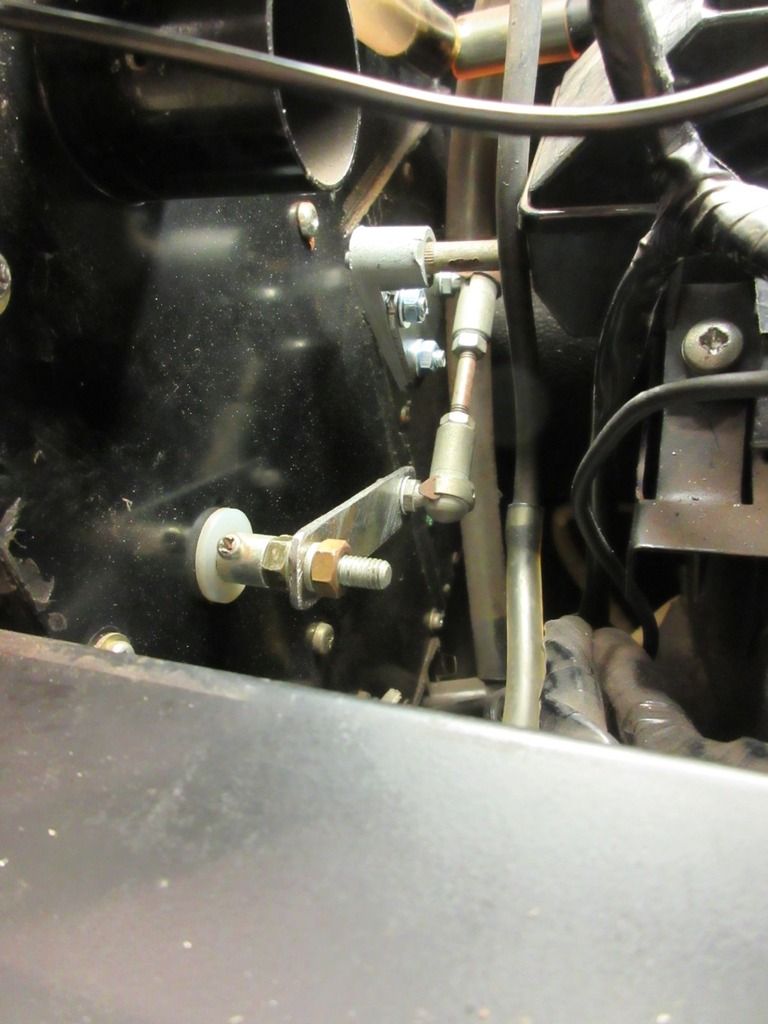

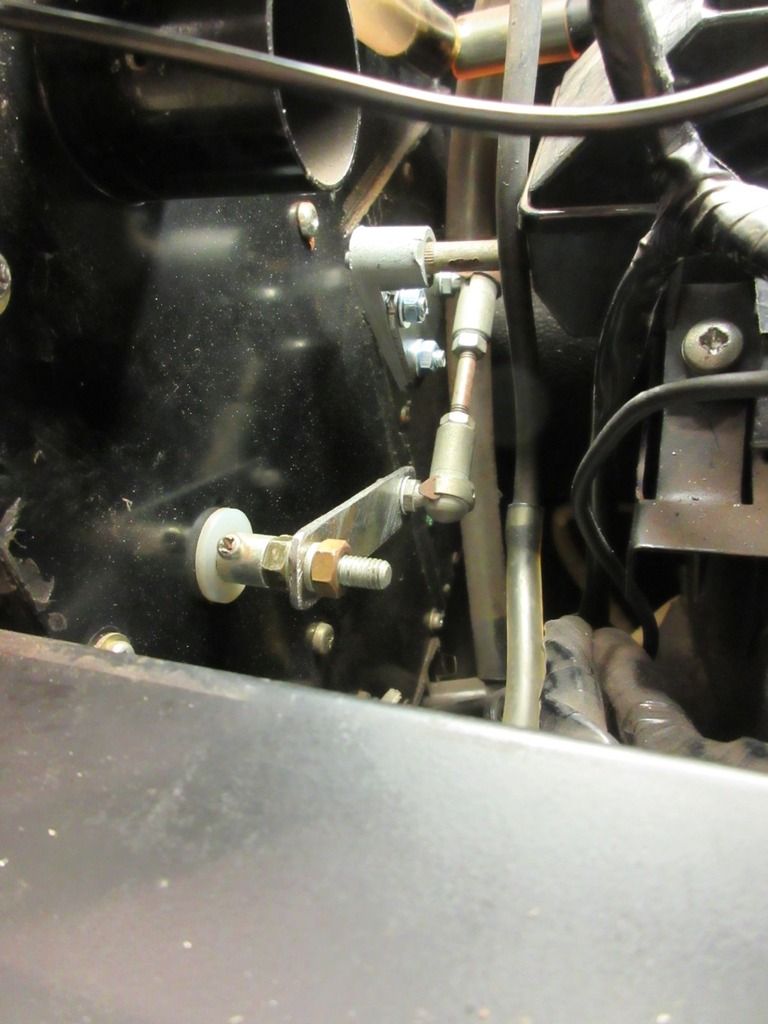

Now that the starter inhibit was fixed, the vacuum advance-retard and ignition timing could be sorted. This system uses the inhibit switch, plus a microswitch on the top of the engine to control the idle speed so that the idle is normal when the engine is under no load (neutral/park) but doesn't get too low when drive (or reverse) is selected. Positive pressure (which comes from the air pump) is fed to one side of the vacuum diaphragm on the distributor and vacuum on the other, controlled by the solenoid valves next to the distributor. I had previously repiped the solenoids and also the air pump so it should be straightforward.

First thing though is to replace the vacuum capsule as the old one has perished and no longer works. This is something which had been unobtainable, but David now has them. My distributor had to be sent off as part of this process.

New capsule fitted and the work can begin. First David confirms the timing mark on the crankshaft pulley on the front of the engine. It turns out that the timing mark was hand-applied to each engine once the pulley was fitted. A replacement pulley would mean an incorrect mark so best to check it first! This is done by using a dial gauge down the spark plug hole to tell when number 1 piston is at the top:

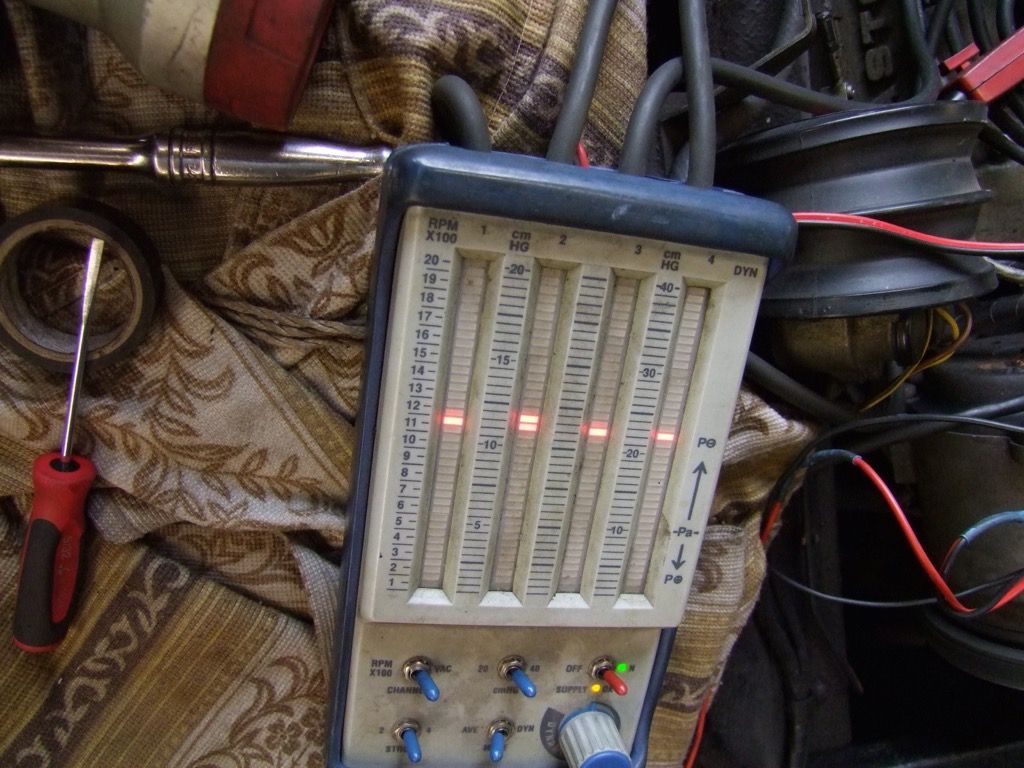

Now the AML test gear can be connected to see things are working as expected. The test operation is in the owners handbook.

So, does it work? No.

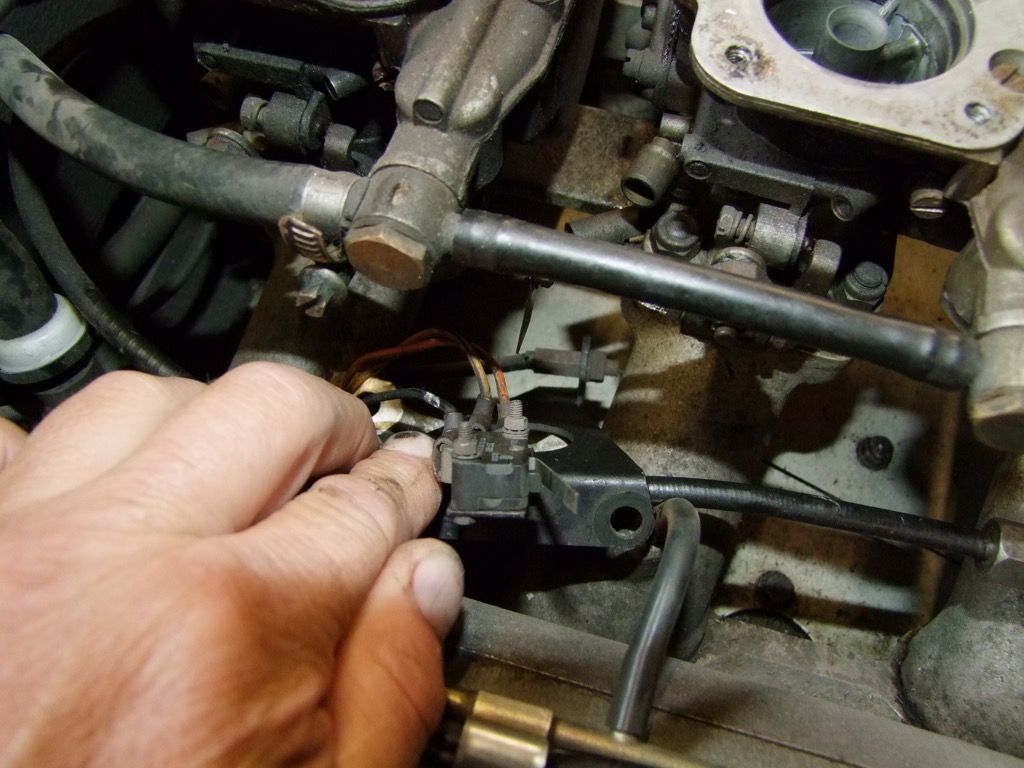

It turns out the microswitch which senses the accelerator is not pressed (idle) is connected backwards!

With this corrected, all works as expected and the timing can be set.

|

|

| Back to top |

|

|

jonc

Joined: 21 Sep 2010

Posts: 584

Location: Cheshire, UK

|

Posted: Mon Oct 19, 2015 3:47 pm Post subject: Posted: Mon Oct 19, 2015 3:47 pm Post subject: |

|

|

The emissions on the car when it was tested for its MOT were not good. I suspected that the carbs were not set up properly. This is job which requires skill and so has been on my (David's) todo list for the car. After a service, and now that the timing is sorted out, the engine can be tuned.

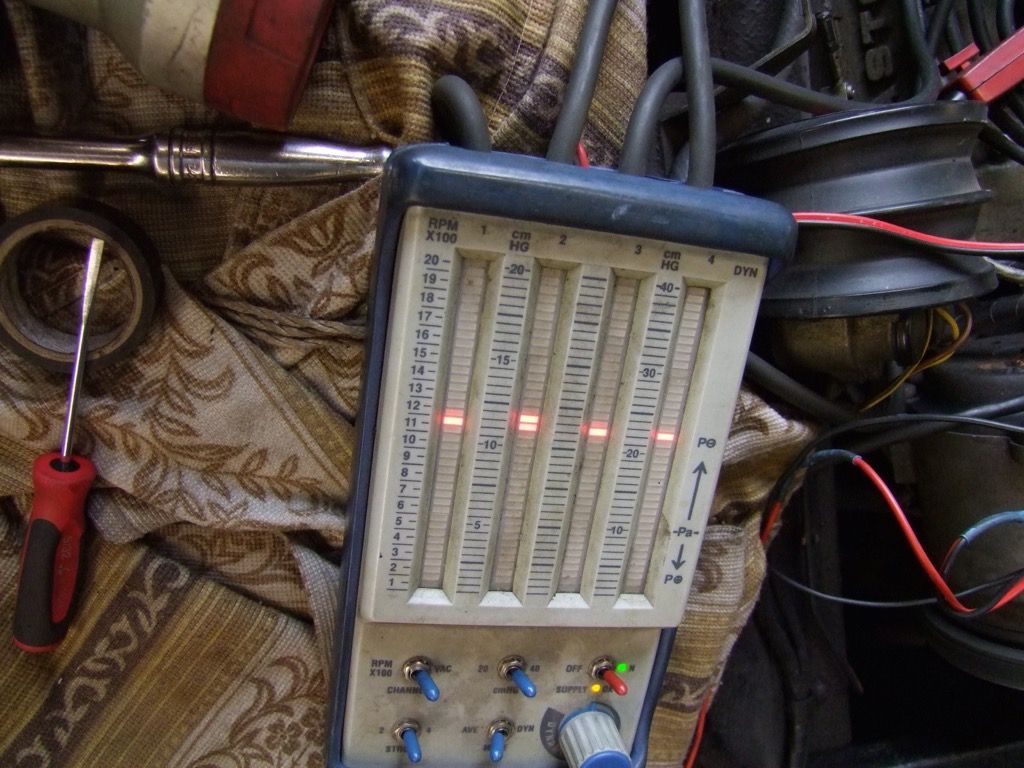

First each carb has its jets cleaned, and the O rings on the idle jets are replaced. The carbs are balanced against each by comparing the vacuum in each ones inlet manifold.

This is how they started out:

It is no wonder the idle was very lumpy. After balancing:

It is quite an amazing change now the is engine set up properly. The car now has a smooth idle, lots more power and a smooth delivery with no coughs , splutters etc. Actually, I think this car now goes better than the blue one! |

|

| Back to top |

|

|

jonc

Joined: 21 Sep 2010

Posts: 584

Location: Cheshire, UK

|

Posted: Mon Oct 19, 2015 4:00 pm Post subject: Posted: Mon Oct 19, 2015 4:00 pm Post subject: |

|

|

Final job before the car goes for its MOT. The David wasn't 100% happy with the brakes. He had already flushed and replaced all the brake fluid but was still not happy. A replacement master cylinder was fitted which has helped improve things:

Off the car goes for its MOT and.. passes.

Hurrah! I can have it back. I haven't driven a Lagonda since 379 left me in May.

Ready to leave DM:

And it arrives home:

|

|

| Back to top |

|

|

jonc

Joined: 21 Sep 2010

Posts: 584

Location: Cheshire, UK

|

Posted: Mon Oct 19, 2015 7:23 pm Post subject: Posted: Mon Oct 19, 2015 7:23 pm Post subject: |

|

|

So, the car is back home - what else is there to do?

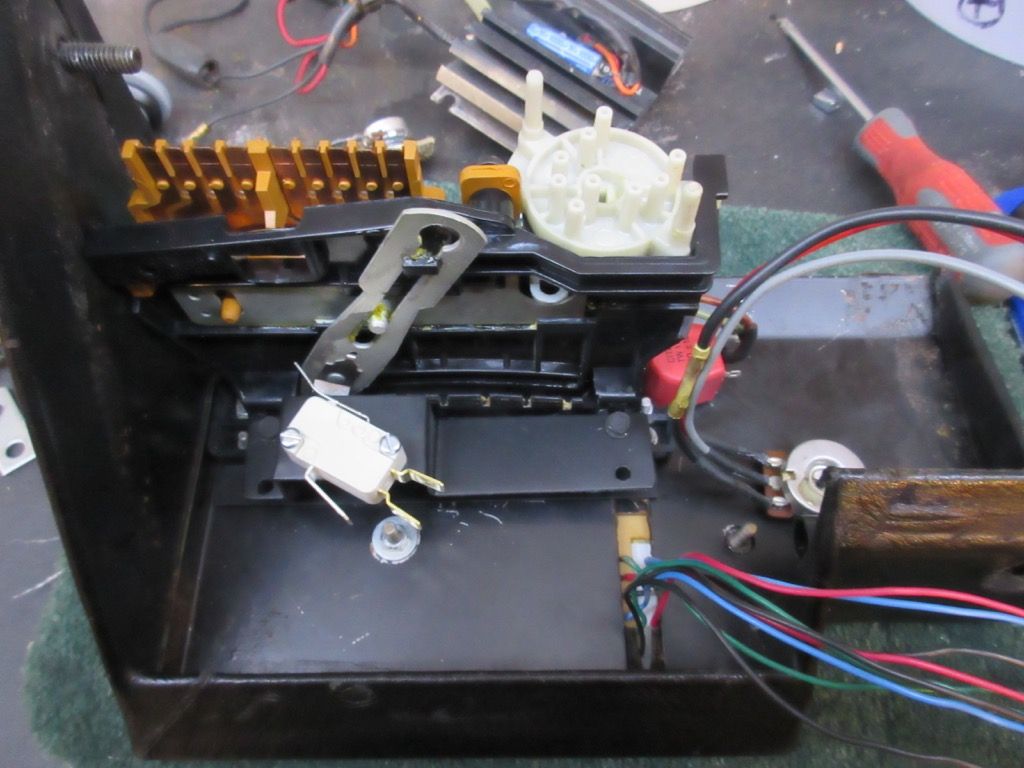

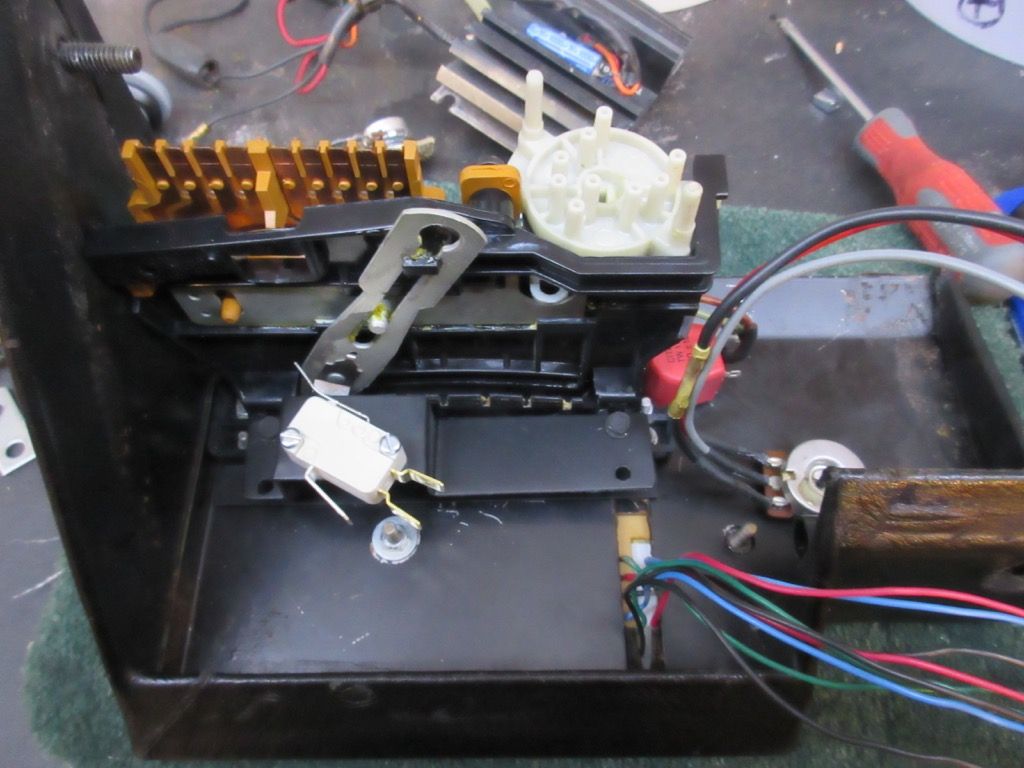

The heating / aircon system has never worked properly while I have had the car. Previously I have replaced the slider switch and fixed the wiring for the blower fan. In the past, the car had been converted to manual operation of the blend flap with a choke-type control mounted below the dash but this never worked properly - the car was always blowing hot air. It is time to sort this out.

First job - the dash has to come apart. The brains of the system, the Programmer is mounted deep behind the instrument panel and so this, and its housing, and the dash top panel have to be removed.

With everything out of the way, you can just see the programmer - it has no hoses connected to it:

It is supposed to control the blend flap of the heater to regulate hot and cold, but this mechanical connection is missing. Fortunately, some years ago and in anticipation of this job I bought the missing parts.

I could now connect it back together:

I was also missing the lever from the heater box end which I have made.

Now the complete system is repiped with silicone hose. The links between the Programmer and Control Head (slider) are numbered using heat-shrink numbers. This is before shrinking:

and after the application of a heat gun:

Each actuator also gets new pipes, and also the feed from the vacuum reservoir under the bonnet and the feed back out to the hot water valve.

This is what came out:

I also made the missing bracket and fitted the missing microswitch for demist mode:

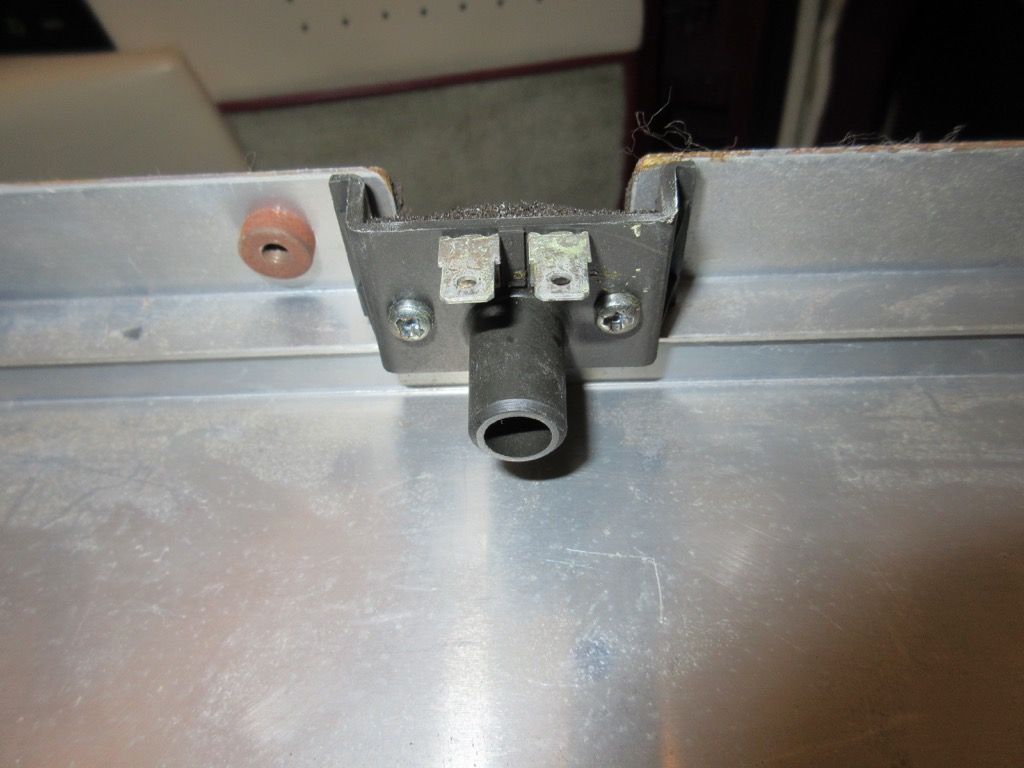

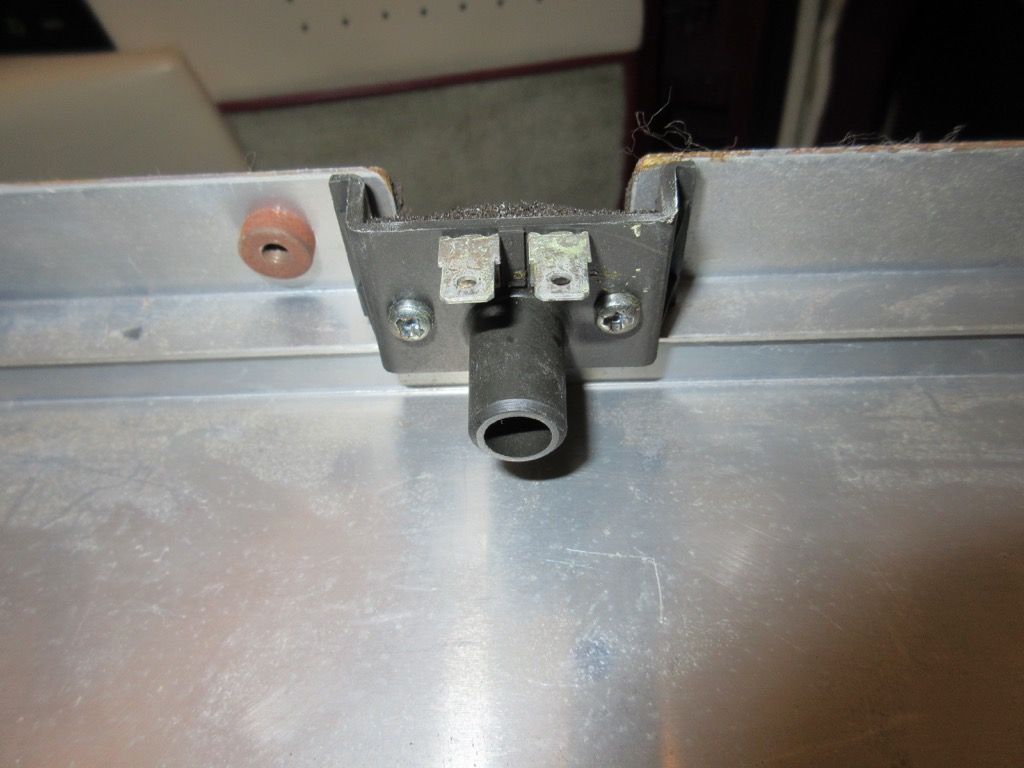

The system senses cabin temperature using air drawn past a sensor mounted behind the dash on the passenger side. On this car there is a small hole at the top of the wood trim and the sensor mounts behind it. There is a tube connected to it to draw the air and the sensor housing is mounted to the dash top:

And its front:

You can see here that there is a break in the wire on the right. In fact, the sensor itself has started to disintegrate.

I fit a replacement thermistor:

Now I should have a working system. Testing it shows otherwise

I had hoped that the faulty thermistor was the reason for modifying the system. Actually, it turns out that there is also a leak in the vacuum actuator in the programmer and so the Programmer appears dead.

Fortunately, I have a spare and so this is fitted.

I now have a working system!

One other point - the AML 'Lagonda Air Conditioning Operation and Fault Diagnosis' training manual has a vacuum diagram which I had been using here. It is wrong! When I get a minute I will put this in the Technical section.

Last edited by jonc on Mon Oct 19, 2015 7:33 pm; edited 1 time in total |

|

| Back to top |

|

|

jonc

Joined: 21 Sep 2010

Posts: 584

Location: Cheshire, UK

|

Posted: Mon Oct 19, 2015 7:31 pm Post subject: Posted: Mon Oct 19, 2015 7:31 pm Post subject: |

|

|

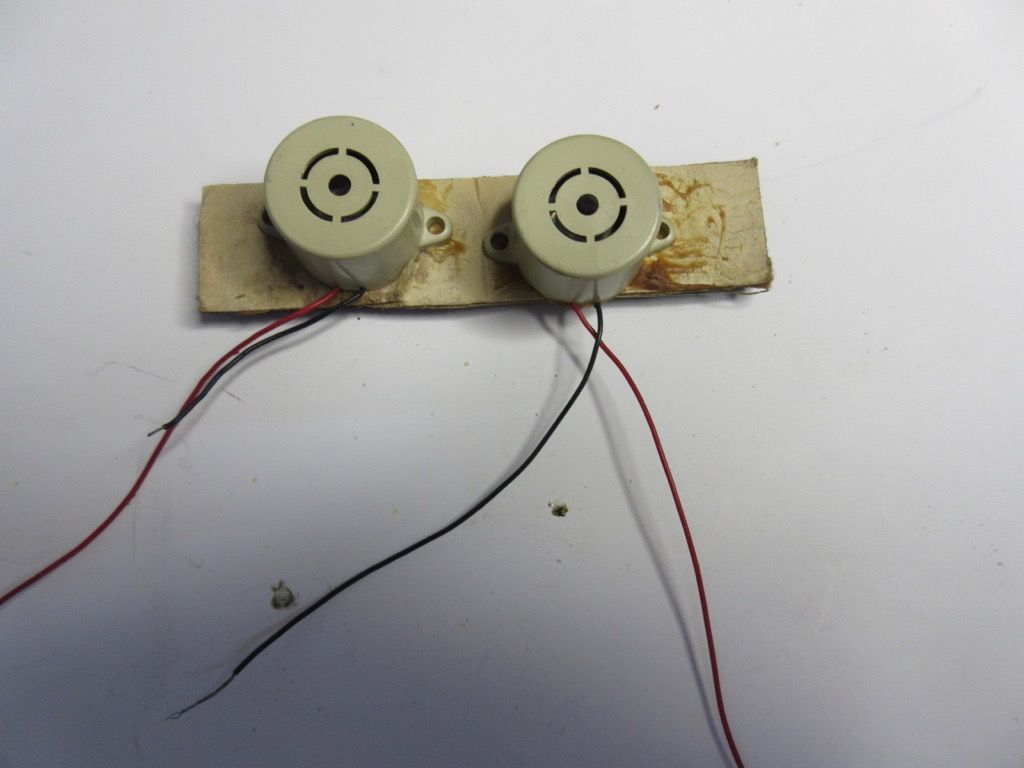

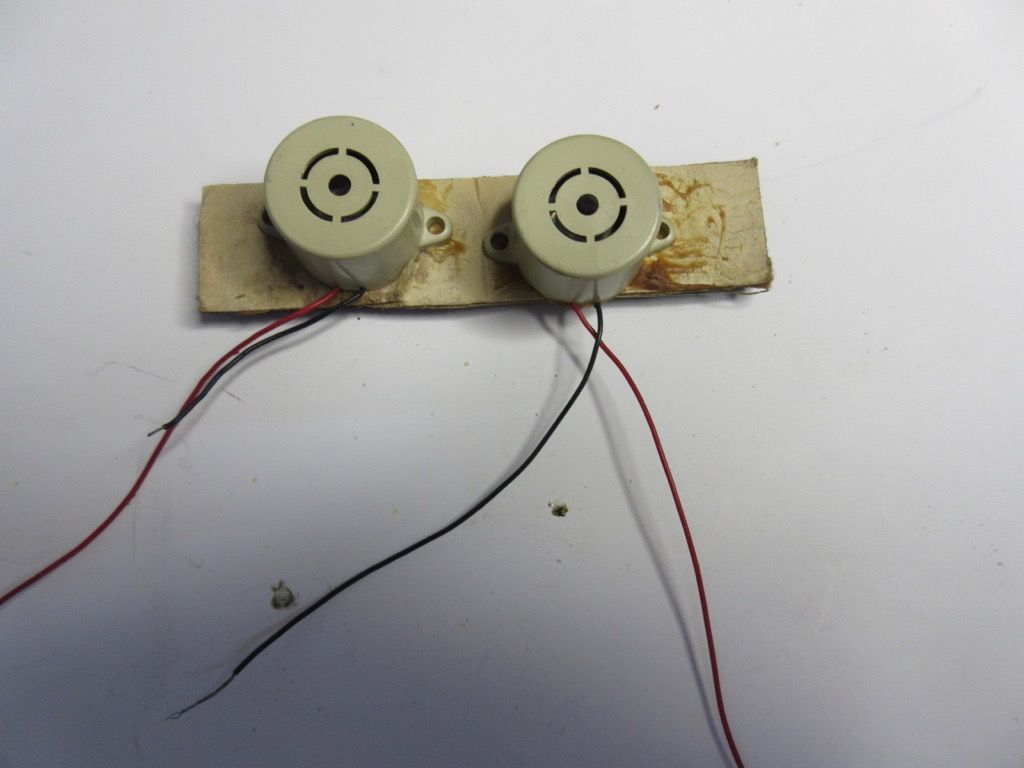

One more job before the dash goes back together. The buzzers for the touch switches have never worked, or even been connected. This is because AML crimped bullet connectors onto the ends of their very fine wires. In the past, someone has tried to disconnect them and snapped the wires. 13379 had screw terminal blocks so AML had improved on the design between '83 and '84.

This is them from 277 - its a quality job:

They are glued on a small piece of corrugated cardboard with velcro on the back. Here is my upgrade:

I have soldered some automotive - quality wires to the thin ones and sleeved the joins. I now have working buzzers.

Now I have the car back I can deal with another niggle - the scissor jack:

The blue one is what was in the car; it is a generic Draper one. While the car was away I bought the correct one. I still don't know what car it comes from, but at least I now have the correct one. Here is it in place in the boot:

|

|

| Back to top |

|

|

Dimitri

Joined: 13 Sep 2010

Posts: 180

Location: Smarden, Kent, UK

|

Posted: Wed Oct 21, 2015 1:59 pm Post subject: Posted: Wed Oct 21, 2015 1:59 pm Post subject: |

|

|

| Fantastic tale Jonathan, the new owner/keeper/custodian will be one lucky chap with this well-sorted example ! |

|

| Back to top |

|

|

Rodolphe

Joined: 29 Nov 2007

Posts: 66

Location: Paris

|

Posted: Wed Oct 21, 2015 11:51 pm Post subject: Posted: Wed Oct 21, 2015 11:51 pm Post subject: |

|

|

|

|

| Back to top |

|

|

Rodolphe

Joined: 29 Nov 2007

Posts: 66

Location: Paris

|

Posted: Wed Oct 21, 2015 11:57 pm Post subject: Posted: Wed Oct 21, 2015 11:57 pm Post subject: |

|

|

|

|

| Back to top |

|

|

Vincent

Joined: 20 Nov 2007

Posts: 1055

Location: Belgium

|

Posted: Sat Oct 24, 2015 10:28 am Post subject: Posted: Sat Oct 24, 2015 10:28 am Post subject: |

|

|

| jonc wrote: |

Now I have the car back I can deal with another niggle - the scissor jack:

The blue one is what was in the car; it is a generic Draper one. While the car was away I bought the correct one. I still don't know what car it comes from, but at least I now have the correct one. Here is it in place in the boot:

|

Volvo cars I think but I need to check...

_________________

Welcome to Paradise ! (FRONT 242)

https://www.youtube.com/watch?v=XS30BC3D5WM |

|

| Back to top |

|

|

Vincent

Joined: 20 Nov 2007

Posts: 1055

Location: Belgium

|

Posted: Sat Oct 24, 2015 10:33 am Post subject: Posted: Sat Oct 24, 2015 10:33 am Post subject: |

|

|

| jonc wrote: |

Now I have the car back I can deal with another niggle - the scissor jack:

The blue one is what was in the car; it is a generic Draper one. While the car was away I bought the correct one. I still don't know what car it comes from, but at least I now have the correct one. Here is it in place in the boot:

|

Volvo cars I think but I need to check...

_________________

Welcome to Paradise ! (FRONT 242)

https://www.youtube.com/watch?v=XS30BC3D5WM |

|

| Back to top |

|

|

Vrije

Joined: 23 Nov 2007

Posts: 440

|

Posted: Tue Oct 27, 2015 8:59 pm Post subject: Posted: Tue Oct 27, 2015 8:59 pm Post subject: |

|

|

Ours looking simmilar and is labelled Jaguar??!!

M |

|

| Back to top |

|

|

jonc

Joined: 21 Sep 2010

Posts: 584

Location: Cheshire, UK

|

Posted: Wed Dec 02, 2015 8:23 pm Post subject: Posted: Wed Dec 02, 2015 8:23 pm Post subject: |

|

|

I remember previously looking at the Jag one but it had an eye on the end instead of a nut. The correct one it now has doesn't have any markings.

Another job to deal with. The wood was generally a bit tatty and in need of restoration. Removed:

and re-veneered, laquered and polished by the ex-RR/Bentley man in Crewe:

and back in the car:

I have also done the sensor upgrade on the LED dash. I have managed to simplify it to fewer electronics changes on the dash now. The outside temp sensor was faulty and so I now have PT1000 platinum resistance thermometers in place of the internal and external ones:

The outside one is mounted below the bumper on a bracket with the ice warning sensor:

Since this is exposed to the elements, I used adhesive lined heatshrink on it:

I also cleaned up the bracket and painted it while I was at it. The new sensor is mounted in a rubber grommet:

The ice sensor was tested (and worked) and I also tested the dash warning light by grounding the wire to it:

Finished job:

The parts manual calls for a 'matched pair' of sensors for int/ext temp since they share the same calibration circuit. No problems with the new sensors since they are made to a much higher tolerance as standard (and they cost less than a tenner each).

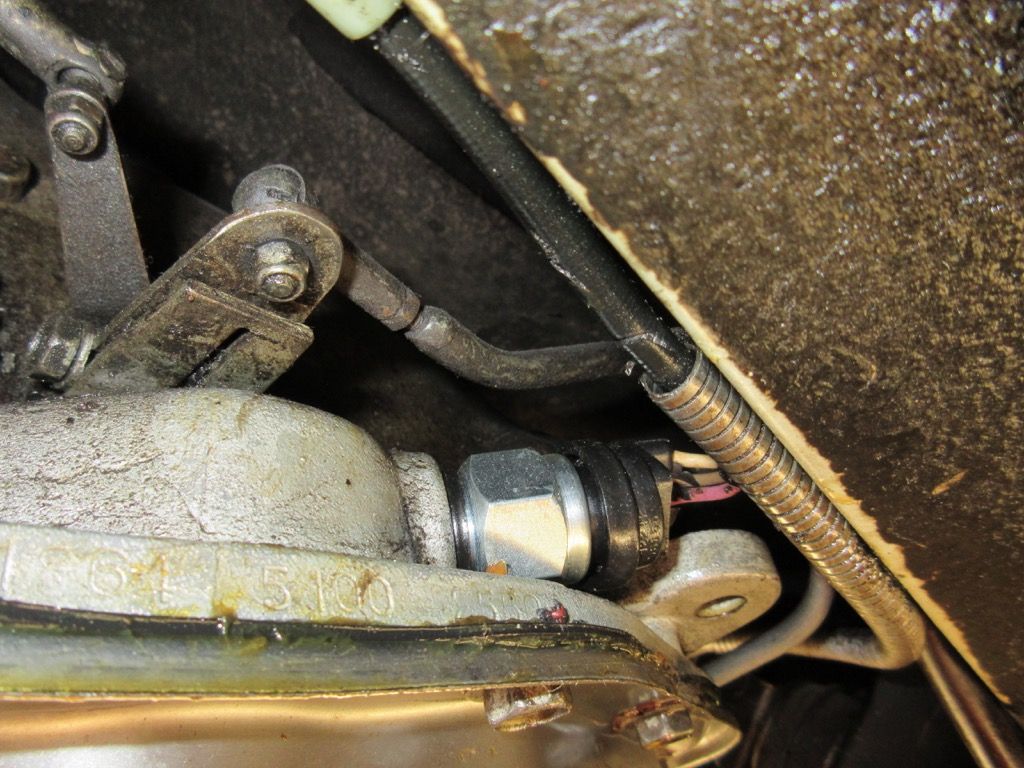

I also replaced the oil temp sensor. Here I used the original sensor housing, with the centre removed:

In place:

|

|

| Back to top |

|

|

Vrije

Joined: 23 Nov 2007

Posts: 440

|

Posted: Sun Dec 06, 2015 10:21 am Post subject: Posted: Sun Dec 06, 2015 10:21 am Post subject: |

|

|

| Where to get those PT 1000 sensors ?[/quote] |

|

| Back to top |

|

|

jonc

Joined: 21 Sep 2010

Posts: 584

Location: Cheshire, UK

|

|

| Back to top |

|

|

|